The Challenges of Drive Chain Performance – Part 2 – Striving for Answers

Lubricating the transmission has always been deemed the key to maximising the transfer of power from the pedals to the wheel and minimising component wear. There is a common mis-conception that chain lube manufacturers are striving to improve the efficiency of a chain above 97-98%. Reducing the 2% loss is not what they’re trying to do, its maintaining the 98% efficiency that is the challenge (essentially trying to keep the losses at a minimum), especially across the wide range of factors (highlighted in Part 1 of this series). Ultimately failing to clean and lubricate the transmission will result in decreased performance, increased wear rates and a higher chance of failure. Transmission efficiency decreases as friction increases which leads to faster wear.

Most traditional chain lube manufacturers approach the problem of trying to deal with the external factors by making their lubricants thick and sticky to ensure they stick to the chain throughout the entire ride, aiming to withstanding the washing effects of rain or surface water whilst lubricating the transmission. Many have successfully produced different lubricants for different conditions offering ‘wet’ or ‘dry’ lubes. As well as the main constituent oils and waxes, most of these products include chemical compounds called Tackifiers which are used to increase the tack or stickiness of the lube to ensure it lasts on the chain. Often found in lubricants, Tackifiers are also used in adhesives and the downside to making lubricants sticky to withstand the environmental conditions is that they also tend to end up collecting dirt. It’s a fine balance between keeping the lube in/on there without picking up too much of the road debris.

Having identified that these environmental factors can have a significant negative impact on chain performance we began a long journey of trying to establish the best and most effective analysis of chain performance using a wide range of techniques and testing methods. This part of the series (of 3) aims to detail some of the testing to date, however it is by no means an exhaustive list of the testing completed to date.

Detailed Academic Assessment – Independent Scientific Assessment of the principals of Chain Performance Systems.

In 2013 Flaér embarked on a research study with leading Sports, Exercise and Health Scientists at Edinburgh-Napier University. Led by Professor Geraint Florida-James and Dr Lesley Ingram (who more recently has been instrumental in helping Mark Beaumont achieve his World Record of cycling around the world in less than 80 days) a project began to measure the performance gains that could be achieved by applying a specialist fluid to the transmission from an on-board system whilst riding. After many months of hard work by the research team, working closely with elite athletes both in the lab and in the real world they reached the conclusion that a chain performance system provided “5% gains and maximum efficiency” with the sub-note “the system produced excellent results under extensive testing”

The advantages of this method – This study utilised real world testing using real performance athletes across a range of environmental factors. It was produced using scientific research with a greater understanding of athlete performance.

The disadvantages of this method – While tightly controlled, the transmission materials varied and athlete performance also varied. Environmental factors/variances cannot be controlled accurately due to the real world.

The findings – From this study it was identified that the type of fluid used, as well as how it was used, was key and that thinner fluids prevented the build-up of dirt in the transmission, an important factor in drivetrain performance. This was very much the beginning of the journey into understanding and controlling chain performance and the effects of lubrication.

Full Tension & CRUD Lab Testing

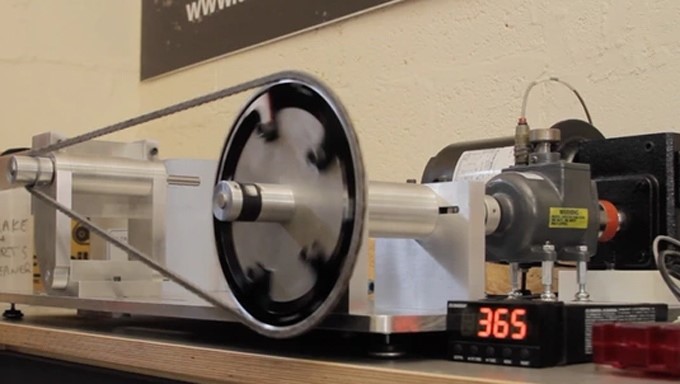

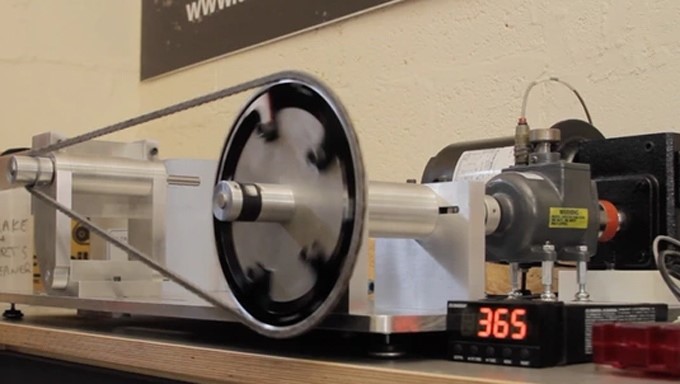

In 2015 Flaér invested in the capability to test chain performance in the lab with a Full Tension Test Rig. This test rig is similar to the equipment used by other brands operating in the area of chain performance such as Ceramic Speed and Muc-Off and was developed by the independent test house Friction Facts in Colorado. Using this equipment and the protocols devised for this setup we are one of only a few companies in the world who are able to accurately and consistently measure chain performance. We can also test in the lab the impact of environmental conditions using our CRUD Tester which allows us to simulate the addition of rain and dirt to see the impact in performance this can have. Our procedures for testing are very rigorous and include two ultrasonic cleaning processes in order to effectively remove any of the special manufacturer’s coatings prior to testing.

The advantages of this method – These test methods allow us to control many of the external environmental variables such as temperature and humidity. We are able to control chain handling/cleansing, lubrication dosages and simulated environment dosages. We can have a steady input and accurately read frictional losses. The system is also flexible to accommodate different chain lengths, chain/cassette configurations & lubrication types.

The disadvantages of this method – While tightly controlled, this method does not simulate the real world where chain efficiency varies depending on the environment, rider input variances and ride time.

The findings – While this testing continues to further refine our knowledge, our results have allowed us to identify the best types of lubrication on the market, their strengths, weaknesses and performance levels across simulated scenarios. It has helped us refine our concept and lubrication construction.

Power Meter (x2) Real World Testing

To support our lab testing, even with the machines simulating different scenarios and environments, we wanted to test things completely in the real world to create further case specific examples of the benefits of our system whilst ensuring a robust process to gathering data, helping to further prove our approach to solving the problem is valid and justified.

With the ever growing trends towards power meters, power data is now more commonly understood and the areas for watt savings identified. Using 2 power meters, a set of Powertap P1 pedals and a Powertap G3 hub, we can now gather lots of power data allowing us to understand how chains perform in the real world. By analysing the rider input at the pedals (power in) to the output at the rear wheel (power out) in real time we are able to see trends in chain efficiency, essentially the difference in power in vs power out. By aggregating the thousands of data points into trend lines to better account for timing and hardware errors we can see some interesting results.

In this example our tester rode with a Revo Via Chain Performance System at a high power input for an extended period of time (approximately 2 hours 40 minutes). At the beginning of the ride the power in vs power out difference was 18 watts from 256 watts to 238 watts – a 7% loss. As the ride progresses past 2 and a half hours the averaged power in vs power out figures converge to 170 watts power in vs 165 watts power out, a loss of only 3% (5 watts), so the losses are seen to be decreasing both in true power terms and as a percentage of input as the ride time increases. In this scenario the rider is gaining 13 watts by the end of the ride having seen the losses decrease from 18 watts down to only 5 watts.

The advantages of this method – This study utilised real world testing using real performance athletes across a range of environmental factors. It is real time and shows the performance differences between input and output regardless of transmission setup.

The disadvantages of this method – The tolerances in the hardware (up to 2%) make analysing the data difficult and can impact the results where margins are so small. Obtaining and controlling accurate data is more difficult.

The findings – The power meter testing has confirmed that there are significant gains to be had throughout a ride with a properly lubricated and maintained chain. The power meter data while accurate has some margin in it so it can be difficult to interpret the data set and accurately account for the errors. Testing continues and refinement of the setup and control measures.

The tests above highlight some of the key areas of testing that we are using to assess chain performance. Like those that have come before we are now also pushing the boundaries of current understanding and seeking innovative new ways to approach the problem and find solutions. To measure the performance of our systems and fluids we do not rely solely on lab based test results for measures of stiction or lubrication friction co-efficient. We extend our testing outside the lab into the real world where bikes are actually used to ensure we understand in more detail the impact of the solutions. Due to all the variables involved it is still not possible at this stage to accurately predict the impact of chain performance for each individual unless controlling for the external environmental factors. However, we’re also working on that for the future too!